Throttle Body Measurement

Depending on your application a larger throttle body can provide some additional power. Fuel delivery is handled as a separate controlled issue. Specifically its designed to measure the temperature of the airfuel mixture that flows through the throttle body into the intake manifold and eventually to the combustion chamber. These parameters should be in somewhat a balance. The throttle body temperature sensor sorry it doesnt have a cool acronym like the tps is also attached to the throttle body and collects data to permit an efficient burning of fuel. The engine will draw only the amount of air it needs.

If the air flow is being measured by an air meter then the tb area vs throttle angle will set the airflow volume and speed thru the air meter. This edelbrock designed throttle body is diecast and fully machined by the supplier prior to assembly with high quality components at the edelbrock factory. Just because a throttle body is rated at 1375 cfm does not mean that the engine will be forced to accept this volume of air. The throttle body in car a provides one of the modern features found in todays cars to help with fuel efficiency. The throttle body simply makes this amount of air available if the engine needs it. It is true that larger throttle bores combined with larger venturis are needed to produce higher power outputs but only when the.

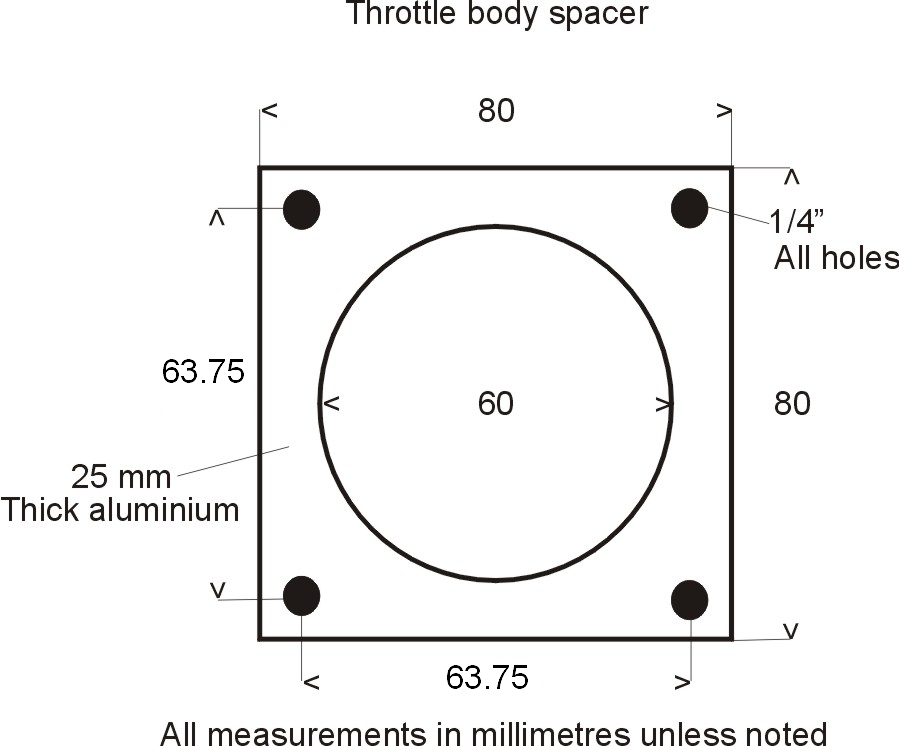

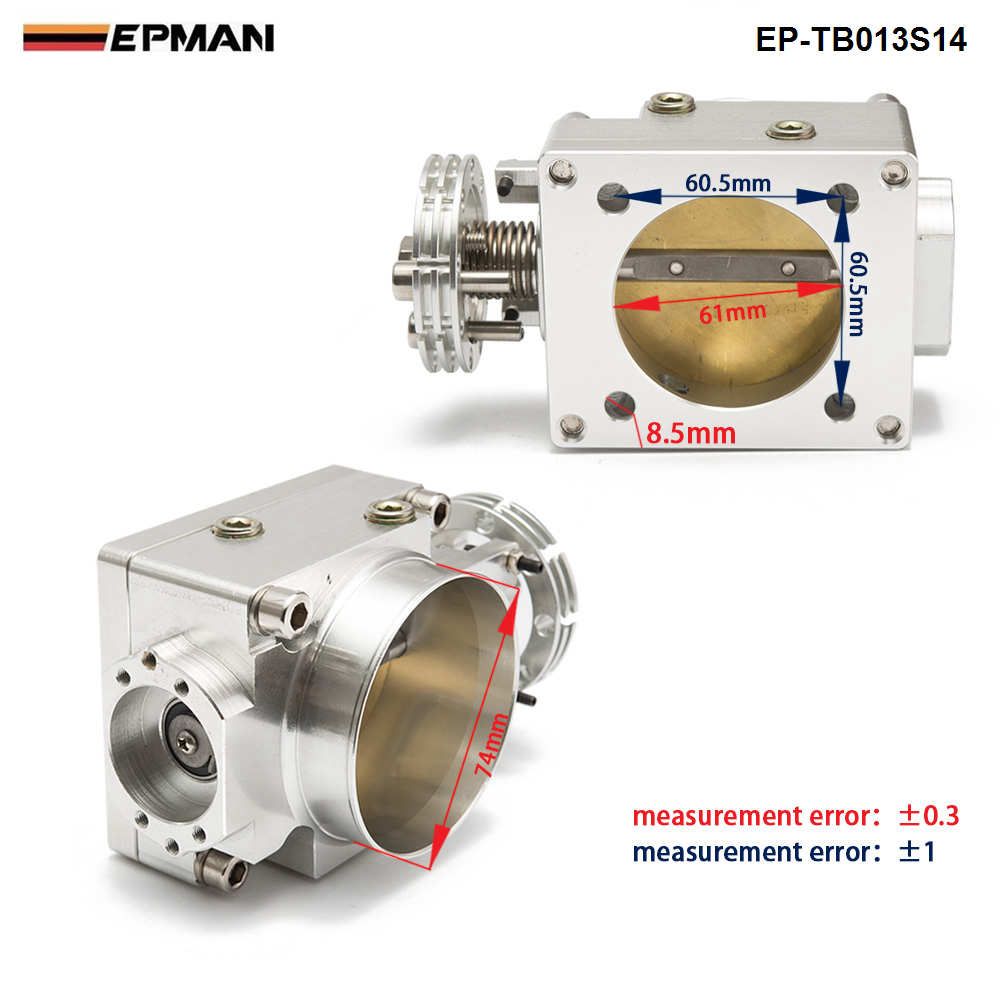

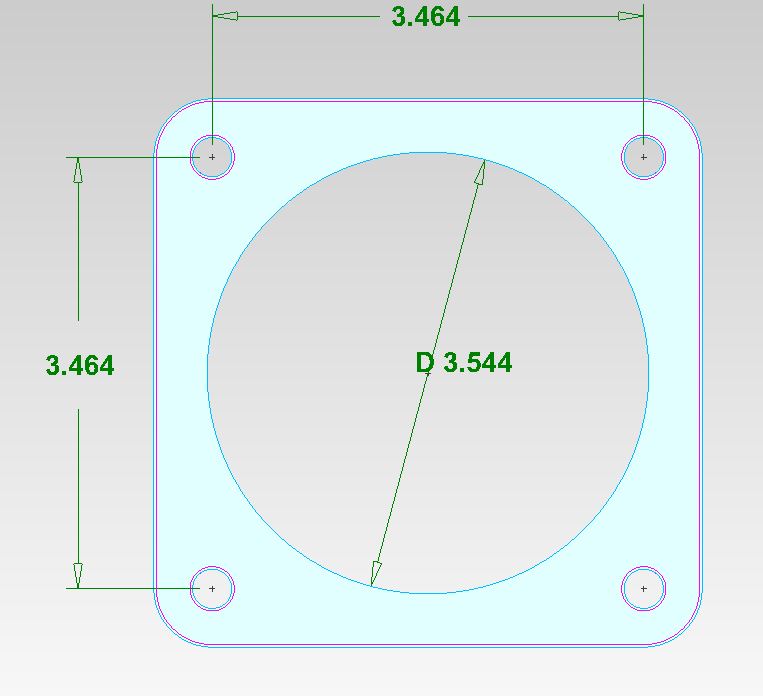

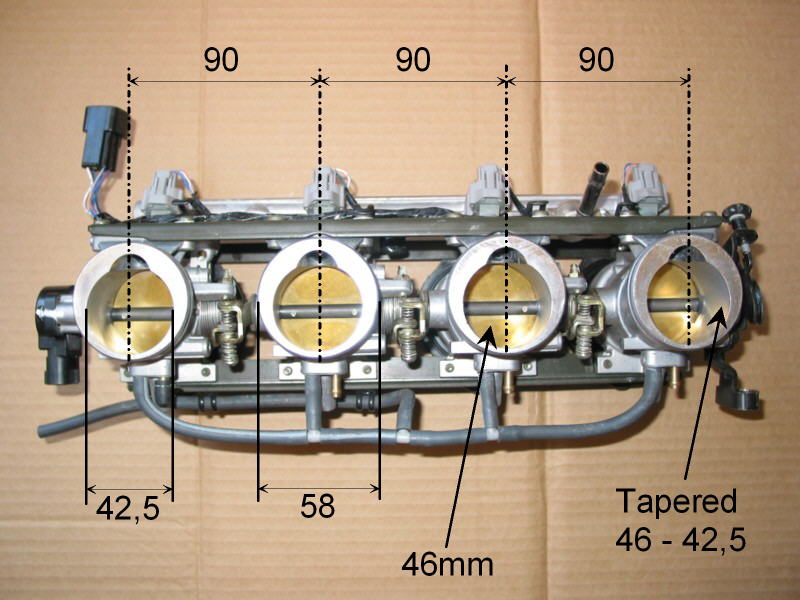

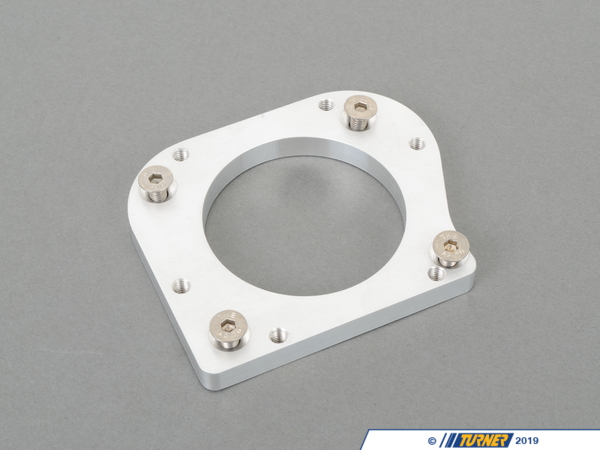

When deciding upon an appropriate throttle bore diameter for your carburetors it is easy to err by over sizing them in the belief that a larger bore size will deliver more power. Place a measuring tape against the inlet hole in the throttle body and take a measurement of the inside of the throttle body inlet. Write the measurement down on a piece of paper. Measurement from base flange to air cleaner flange is 253 inches. Another way to look at this is the throttle body is sized for max airflow and rpm of the engine displacement with some tolerence. In 1988 the first drive by.

This measurement is known as the inlet diameter and is a good measurement to have if you are fitting a cold air intake or supercharger to your current engine. Since the introduction of the ls engine in 1997 there have been several variations of throttle bodies. Cruise control systems too were connected via cable to the throttle body controlling engine speed with an electronic or vacuum motor. In addition to keeping fuel flow to the engine restricted to only what it actually needs the throttle body also houses sensors telling the car computer how the fuel air mixture is working. Until the late 1980s the throttle body was controlled by a cable connected directly to the accelerator pedal which put the driver in direct control of engine speed and power. Throttle body and main venturi sizing.

Most auto manufacturers measure airflow at peak rpms then choose a throttle body diameter to ensure that 50 throttle will produce exactly 50 airflow. Precision throttle control is provided by a progressive linkage with provisions for a 700r4 style throttle valve cable. They have ranged from the original cable driven three bolt 78mm all the way up the 90mm electronically controlled four bolt found on the ls3. This results in a more gradual response that drivers who are not interested in performance would value because they equate it with smooth drivability.

Random Post

- erin krakow body measurement

- very body measurement

- body fat measurement san diego

- body measurements when buying jeans

- body measurement application

- online body measurement calculator

- calculate bmi using body measurements

- where to take body fat percentage measurement

- ideal body measurements female

- marisa tomei body measurement

- body measurement lesley ann warren

- visual of body measurements

- where to take body measurement

- how to put body measurements in myfitnesspal

- karen gillan body measurement

- aftab shivdasani body measurement

- andrea torres body measurement

- nicole maines body measurement

- bmi based on body measurements

- bra cup size measurement uk

- body measurements for army

- template for body measurements

- body measurement ratio calculator

- mohit malik body measurement

- kushal tandon body measurement

- michael clarke duncan body measurement

- ameesha patel body measurement

- women's body measurement chart weight loss

- bra size victoria secret

- body measurement dress size

- garment measurements vs body measurements

- dollshe pure body measurements

- becky lynch body measurement

- diane kruger body measurement

- dahua human body temperature measurement

- drafting body measurements

- cinta laura body measurement

- body measurement chart male fitness

- most accurate body fat measurement method

- define body measurement

- ideal body measurements calculator

- zulay henao body measurement

- yoga body measurement

- t shirt body width measurement

- sami zayn body measurements

- natti natasha body measurements

- emma stone body measurement

- nargis body measurement

- bra size ratio

- dexter jackson body measurement

.jpg)